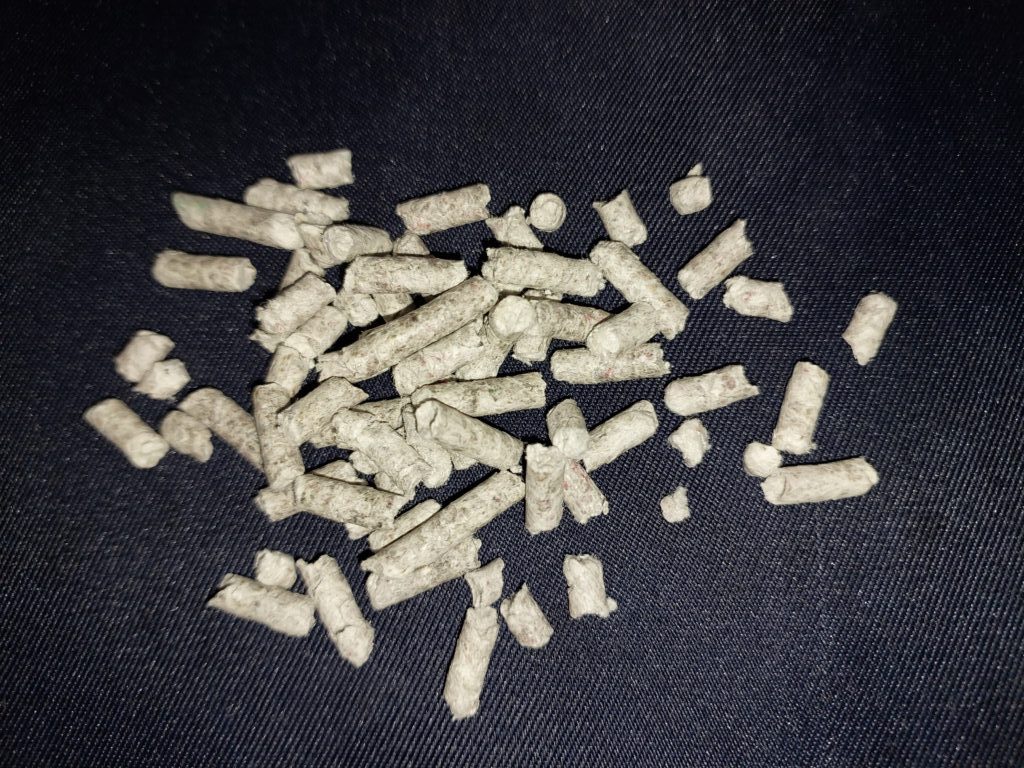

1. Properties 1.1 Appearance: Grey fibre

1.2 Fibre Type: Recycled Cellulose 2.1 mm

1.3 Description: Round and un-crimped pellets

1.4 Fibre Diameter: 18 μm

1.5 Fibre count per gram: 720 x 10⁶ (Calculated)

1.6 Surface Area; 25 000 cm²/g

1.7 Flash point: 300 ºC

1.8 Auto Ignition Temperature: Absent

1.9 Physical State: Solid

1.10 Moisture Regain: 85%

1.11 Solubility in water: Not soluble

1.12 Tensile Strength: 620 to 896 N/mm² min

1.13 Packaging: 600g water soluble bags

2. Typical use in Concrete / Cementitious applications

3. Advantages

3.1 Reduces plastic settlement and plastic shrinkage cracking in concrete formed during hardening stages

3.2 Provides 3 Dimensional Reinforcing in concrete for crack control

3.3 Reduces water permeability thus helping to prevent from dampening as well as helping to avoid corrosion in reinforcing steel used in concrete

3.4 Engineered in pellets for improved distribution in concrete matrix

3.5 Improves concrete hydration

3.6 Adds Impact and abrasion resistance

3.7 Increase shatter and spalling resistance

3.8 Explosive spalling resistance

3.9 Sustainably sourced from recycled paper

Caution: The addition of fibres helps to effectively limit plastic shrinkage and reduce cracks normally formed during dry shrinkage of concrete as well as improving other properties of the same. It must not, however, be used as a replacement for structural or load bearing reinforcement materials.

4. Dosage rate and directions for use

4.1 Dosage: 600 g/m³ to 1500 g/m³ (depending on Engineer’s specifications) or approximately 0.2% by volume.

4.2 Directions for use:

Transit mixer: Simply add fibre bag in to revolving truck mixer, according to dosing recommendations.

Mixer: Sprinkle fibres in the rotating mixer on top of sand and stone. Allow dry aggregates to mix for 30 seconds, add cement, balance of water and allow rotating as usual;

Manual mixing: For best results, sprinkle fibres over dry aggregates (sand/stone) and manually mix as usual, add cement and mix once more before adding water